I designed and manufactured a custom table for an ocean-going yacht. I made a table that takes up as little space as possible while providing “deployed” functionality superior to what it is replacing. The materials are selected to stand up to the hard-wearing, corrosive marine environment of salt and humidity, and the bashing around that can occur in a cramped cabin while underway.

When deployed with the top closed, one or two users can sit on the starboard bench seat and dine comfortably, while still allowing clear access through the cabin to the front berth and head. The lower swingarm is offset towards the center of the boat to provide plenty of knee clearance and carry the load better when the table is extended. The rounded corners match the curved surfaces of the boat to harmonize aesthetically, and avoid dangerous points if someone loses their footing.

When fully deployed, 4 people can cozily share a meal by sitting on the port side bench as well, and people can still squeak by to get through the cabin if needed.

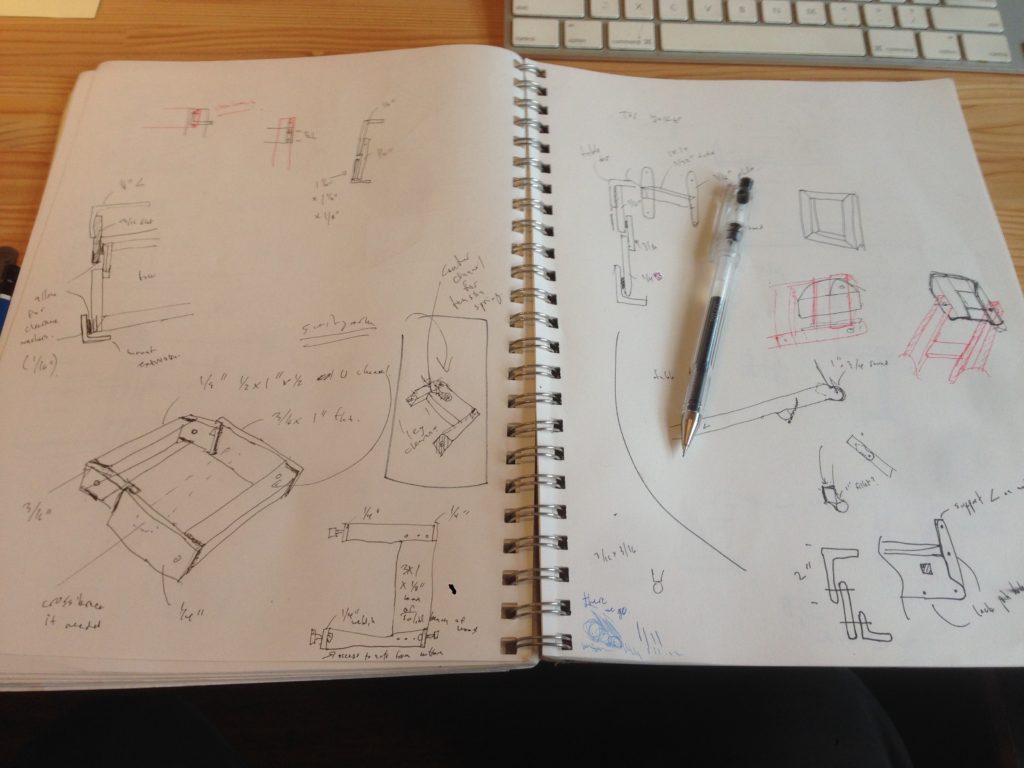

Like most of my projects, I started with an initial concept, and lots of sketching. It took many pages of sketches to clarify how things should stack, interface, translate, and be constrained, along with initial concepts for construction details.

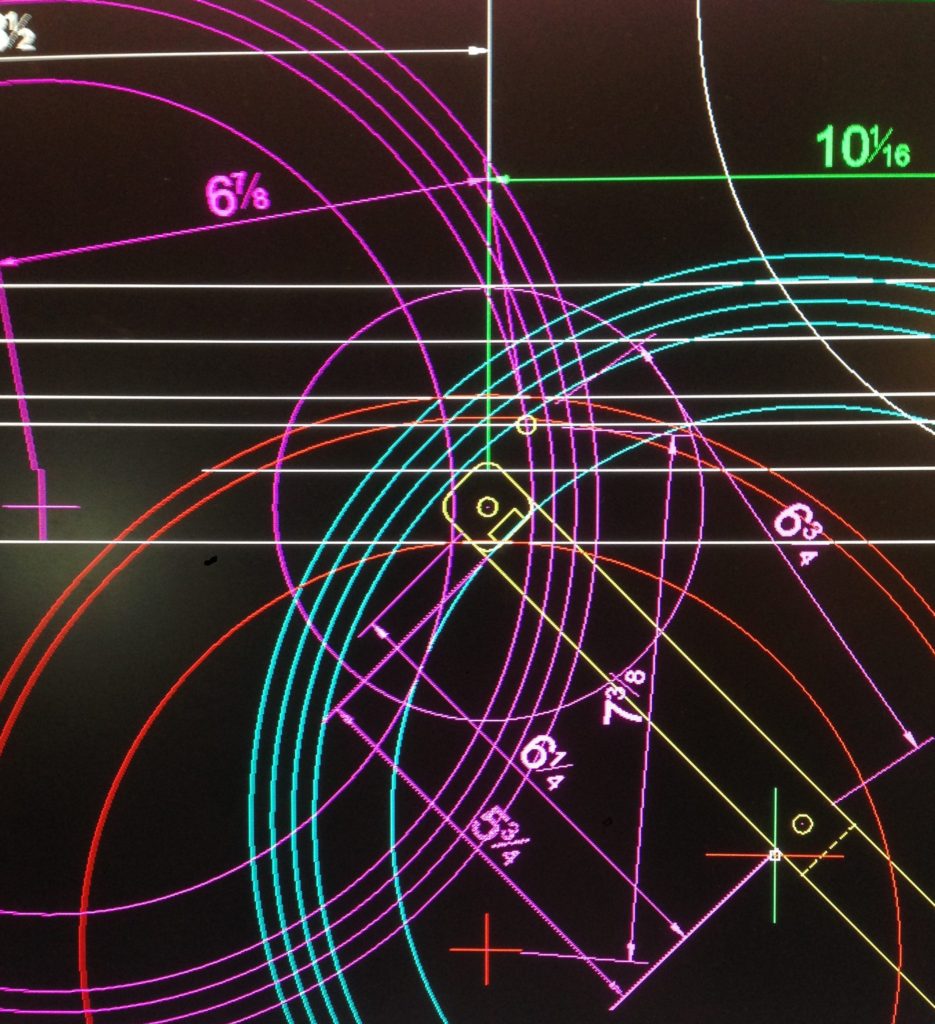

I moved into 2D CAD to do a scale drawing and make sure everything would fit. The constraints when translating from the ‘up’ position to the ‘down’ position were the required table height and the overall height of the bulkhead that the table stores against. Here I’m working out swing radii and how extended an assist spring would be under different angles.

Not all of the parts were fully defined before I started building. I didn’t come to a complete solution without some trial and error for tolerances, which tested my abilities as a machinist. Close tolerances are critical to having the table operate properly.

I shopped out the welding of the aluminum swingarm frames since I do not have access to a TIG welder. I designed a spring assist to the mechanism but decided the added weight and complexity was not worth the minor potential usability improvement. The finished table can be easily operated by one person.

After machining of the frame components, I did a test install in my shop to verify everything. The design relies on a 4-bar linkage to pivot and translate the table surface, with hitch pins to lock the table in the two positions. Because of the linkage the table is never ‘out of control’ even when not locked in place, which provides for safe operation in a moving sailboat.

The apron surfaces are made of reclaimed teak from the old table which this unit replaces. The top surfaces are marine grade mahogany plywood. All wood surfaces are finished with 3 coats of polyurethane spar varnish, an extra-durable marine coating. The major mechanical components are 6061 aluminum extrusion with stainless steel fasteners and hinges. The aluminum parts were finished with a wire brush wheel chucked into my milling machine.

The reclaimed teak along with the edge grain of the mahogany marine plywood form a nice gradient of wood tones. The amber tint of the spar varnish helps it blend and match the other wood surfaces in the boat cabin.

The bulkhead is reinforced under the sink with marine plywood blocking to handle the significant torque created by a 40″‘ long lever.

While underway, the table leaves are kept together with a leather strap snapped to screw-in studs.

When it’s all buttoned up, it practically disappears, contributing to a much needed sense of space if you’re cooped up in the cabin on a rainy day or a long sea passage.